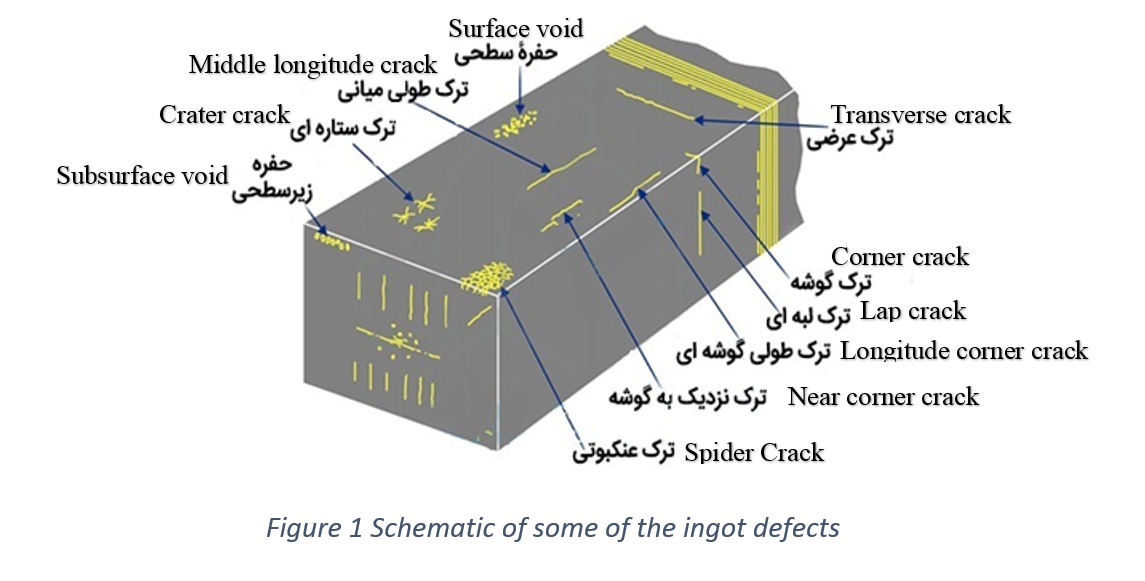

In this article, the defects that are produced during and after casting ingots in Continues Casting Machine (CCM), are discussed.

-

General Information

The defects of casting ingots by continues method appear during the solidification. These defects could be seen on the surface and in central parts of the casting product and could have negative effect on production efficiency. In some cases, these defects can stop the machine from working and as a result the metallurgy engineers and casting designers should be aware of the causes of these defects and know the things which must be done in order to prevent these defects to happen or predict them.

-

Different Types of Ingot Defects

Ingot defects are divided into three categories:

- Internal Defects

- Surface Defects

- Profile Defects

-

Internal Defects

These are cross sectional defects that are not visible from the surface of the product and are effective in the final products like iron beam and rebar.

1.1. Different Kinds of Internal Defects

– Segregation cracks in center and central porosity (segregation cracks, half long cracks), three-point cracks (facial cracks)

– Diagonal cracks (corner cracks), casting lubricant inclusions, spherical inclusions, cluster inclusions like sub surface inclusions and gas holes.

| Defect | Cause of the defect | Effective parameters | Solutions |

| Side transverse cracks | Deformation of ingot’s skin | Existence of sulfur with the amount of 0.02% | – similar to pulling roller mode

– deforming during bending and facing more than usual |

| Transverse cracks of pulling roller | Compression of the ingot’s skin | Unexamined speed of casting in both upper and lower skin | Reduction of the contact pressure of rollers |

| Longitude cracks of central line | Swelling of slabs in the tip of the molten puddle | – casting speed and length of the machine

– shrinkage in ingot’s thickness |

– steepening rollers in the tip of the molten puddle

-like facial cracks |

| Three-point longitude cracks | Swelling of the wide face of the ingo | The chemical composition of steel | Like facial cracks |

| Longitude cracks in corners or laps (diagonal cracks) | – swelling of the narrow face in ingots

-rhomboidity in ingots -non-uniform cooling |

– slope of the narrow face

-alignment of the flow of pouring melt and temperature of casting |

-detecting the slope

– adjusting the holder of the narrow face -controlling the spay cooling system |

-

Facial Defects

2.1. Different Kinds of Facial Defects

– longitude and transverse facial cracks

– crater cracks

– needle voids

– carburizing

– symptoms of deep oscillation

| Defect | Cause of the defect | Effective parameters | Solutions |

| Longitude cracks between the laps of each face | – lack of uniformity in cooling and backup in mold

-stress is more than the strength of the skin of the ingot |

– chemical composition of steel

– temperature of casting – gating system – width of the ingot – lubricant of casting – state of the mold and alignment – absorption of Al2O3 in lubricant – oscillation |

– reforming the surface of the mold

– inspecting the mold for the second time – changing the casting lubricant – inspecting the protection of molten liquid system |

| Longitude cracks in corners | – lack of uniformity in cooling and backup in mold

– stress is more than the strength of the skin of the ingot |

– chemical composition of steel

– temperature of casting – radius of the lap – slope of the mold – oscillation |

– changing the pipe molds

– inspecting the slope of narrow face – increasing the alignment of the mold |

| Transverse cracks in corners | – severe cooling and repetitive local cooling

– facing and bending at temperatures below 800℃ |

– chemical composition

– the amount of C, Mn, V and Nb |

– decrease of the flow of the cooling water

– inspecting pouring sprays |

| Crater cracks | – severe cooling and repetitive cooling with reheating

– hot cracking due to erosion of Cu from mold |

– alignment of molds and rollers of the mold

– the slope of the mold |

Inspection of cover of the surface and alignment of the mold |

-

Profile Defects

Profile defects cause deformation in the cross section of the real geometrical slope of the product. There are different reasons which are the source of profile defects but they are generally related to shortness or non-uniformity of the cooling system. As a result, in most cases profile defects or cracks appear. High speed and high temperature of casting along with the aforementioned reasons, prepare the suitable condition for these defects to appear and they affect the form of the products like iron beam and rebar.

3.1. Different Types of Profile Defects:

Transverse and longitude dents, swelling of the ingot, changes in the width, bending and acinaciformation, not being straight, being rhomboid, being ellipsoid.

-

Causes of the Crack:

In continues casting, cracks exist on the surface and on the solidification face. They appear because of stresses and strains due to thermal and mechanical loading. The stress that the material is subjected to is so important at that unsuitable temperature interval. The temperature interval for surface cracking is between 800°C to 900°C. But internal cracks occur at temperatures near the solidification curve of the steel. You should be careful about the phenomena which are related to weakening the inter-grain bonds. Fusible metals like copper, brass and tin which pass the surface and reach the grain boundaries have such an effect. Due to existence of FeS layer or (Fe, Mn) S inclusions in grain boundaries, cracking is accelerated. Through moving from mold to the cutting torch, ingot is subjected to loads which if their stresses and strains are too high for the steel, it will result in failure of the product.

Loading phenomena which occur in this path:

– Swelling of the skin of ingot due to ultrastatic pressure

– Distortion of the ingot’s skin like becoming rhomboid or ellipsoid

– Tensile stresses due to outward forces or mold’s friction

– Bending the ingot skin from vertical mode to arcuation

– Facing the ingot skin or solidified ingot to horizontal mode

– Bending the ingot skin due to misalignment of guiding rollers

– Bending ingot skin with deformed rollers

* It is possible that stresses that are produced due to mechanical phenomena will be intensified by thermal stresses.

-

Slags

Slags are similar to ice particles and are floating on molten metal surface, under the lubricant layer of casting. When they reach the solidified skin, attach to it and will be pull out with it. It is difficult to detect them on the string surface and they are usually detected from irregularities caused by oscillation of slag inclusions and open voids. The cause of formation of slag is low turbulence on the surface of the molten metal in mold and low temperature of casting. The angles of the entrance of floating nozzles have a strong effect on the formation of slags.